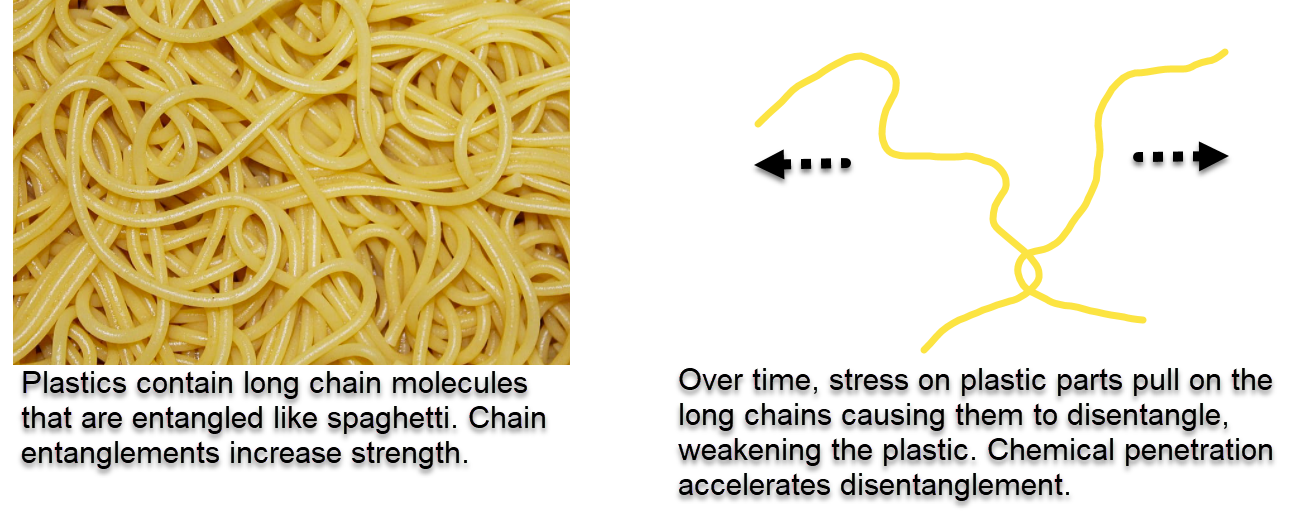

Rigid plastics parts get their strength by the entanglement of the long polymer chain molecules that make up the plastic. Over time, the long polymer chains gradually disentangle from each other during the use of the plastic part causing the plastic part to become weaker and weaker.

A CASE STUDY

The following case study is the property of Plastic Expert Group and cannot be copied or distributed without prior permission. Our case analysis does not imply that this specific plastic failure will happen systematically. Every case is unique and should be treated accordingly.

PROBLEM: ENVIRONMENTAL STRESS CRACKING (ESC): WHAT IS IT AND HOW CAN I STOP IT?

Rigid plastics parts get their strength by the entanglement of the long polymer chain molecules that make up the plastic. Over time, the long polymer chains gradually disentangle from each other during the use of the plastic part causing the plastic part to become weaker and weaker. Eventually, the plastic part becomes brittle. Exposure of plastic parts to chemicals that are absorbed into the plastic, causes the plastic to soften allowing the long polymer chains to be pulled apart and disentangle from each other at a faster rate. Once the plastic becomes brittle, the plastic part cracks and fails.

QUESTION: HOW CAN I DETERMINE IF A PLASTIC PART FAILURE WAS CAUSED BY ESC?

We use a series of forensic tests including optical microscopy and/or scanning electron microscopy (SEM) to determine if a plastic part failed by ESC. If these tests indicate ESC failure, we utilize chemical analysis techniques including FTIR, GC-MS, and LC-MS to identify the chemical that causes the ESC failure.

SOLUTION: WHAT CAN BE DONE TO KEEP PLASTIC PARTS FROM FAILING BY ESC?

Some rigid plastics are crystalline and long polymer chains are locked together by the crystal structure so the polymer chains cannot disentangle from each other. If a plastic part is likely to be exposed to a variety of chemicals during its use, it is best to use a highly crystalline plastic that is naturally resistant to most chemicals. We are experts in plastics and can recommend the best plastic material that will be resistant to the chemicals used in the application.